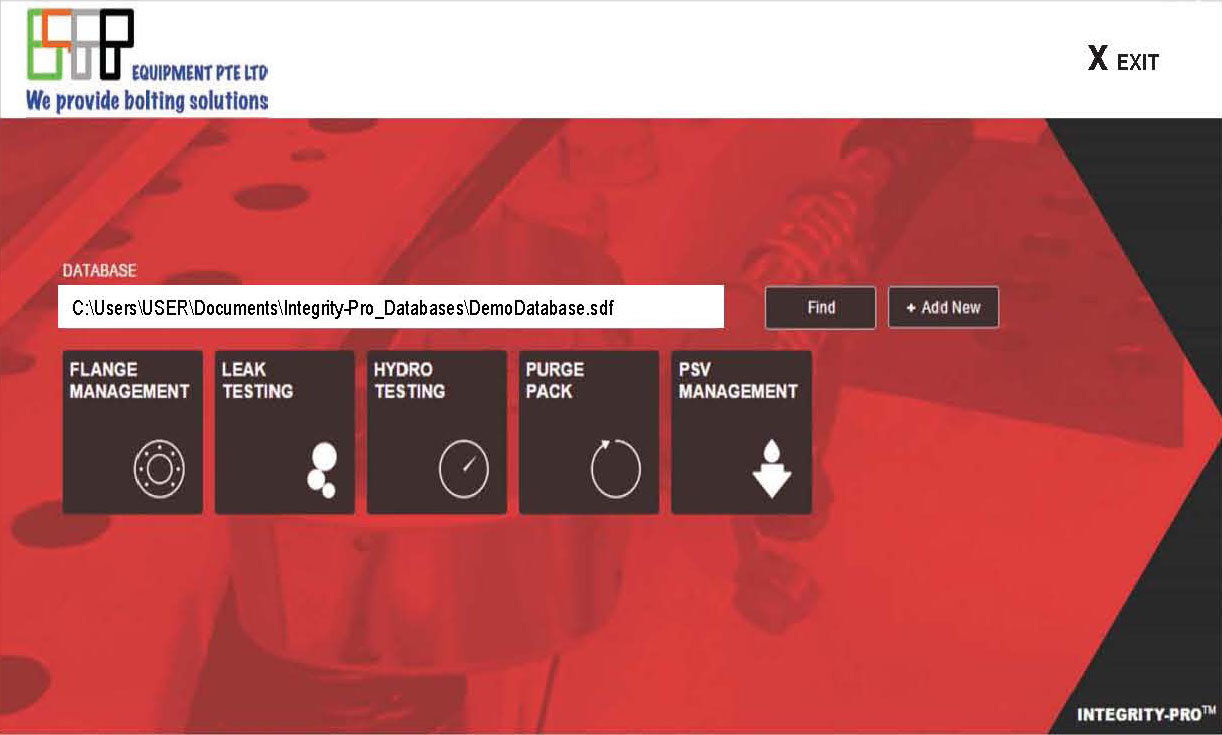

Flange Management / Joint Integrity Software

INTEGRITY-PRO Joint Monitoring software is a bespoke database system specifically developed to plan, monitor, control and provide traceability of flanged joints and connections. This database system interacts with the “Tool-Pro Controlled Bolting Software” calculation engine, runs on the standard Windows operating system and does not require the use of third party database servers. It has been adopted by major plant operators as an essential management system due to it’s simplicity and comprehensive covering of the plant and related maintenance. Offering data gathered from years of industry experience, Integrity Pro can provide bolt tightening data including bolting patterns, torque and tensioning figures, procedures, techniques and recommended controlled bolting equipment. Based on the information entered, the Integrity-Pro software will analyse all of the data and produce a complete calculation sheet along with the required torque or tension figures to ensure an accurate and correctly bolted joint is achieved. Integrity-Pro can also create a specific tightening procedure for each bolted joint, which can include specific information such as any special remarks all of which can be easily entered into the software by the user. It also includes basic information for standard flanges, wafer check valves, spade and spacers, and swivel flange assemblies. Integrity Pro joint integrity database management system is used to support bolted joint inspection and maintenance and/or leak testing activities raising safety levels across the industry in which it applies.

Full traceability and control of all activities

associated with the joint/connection including:

• Joint disassembly/breakout

• Machining/re-facing

• Joint assembly

• Bolt tightening

• Testing. (Hydrostatic, Pneumatic, Nitrogen or Helium)

• Leak history and incidents

Interacts seamlessly with “Tool-Pro Controlled Bolting” software to provide bolting calculations and data for :

• BS1560/ANSI B16.5 standard flanges

• MSS SP44 standard flanges

• API 6A and 17D standard flanges

• Clamp type connectors(Techlok, Grayloc, Galperti. and Destec)

• Non-standard joints, i.e. pressure vessels, heat, exchangers, compact flanges, etc.

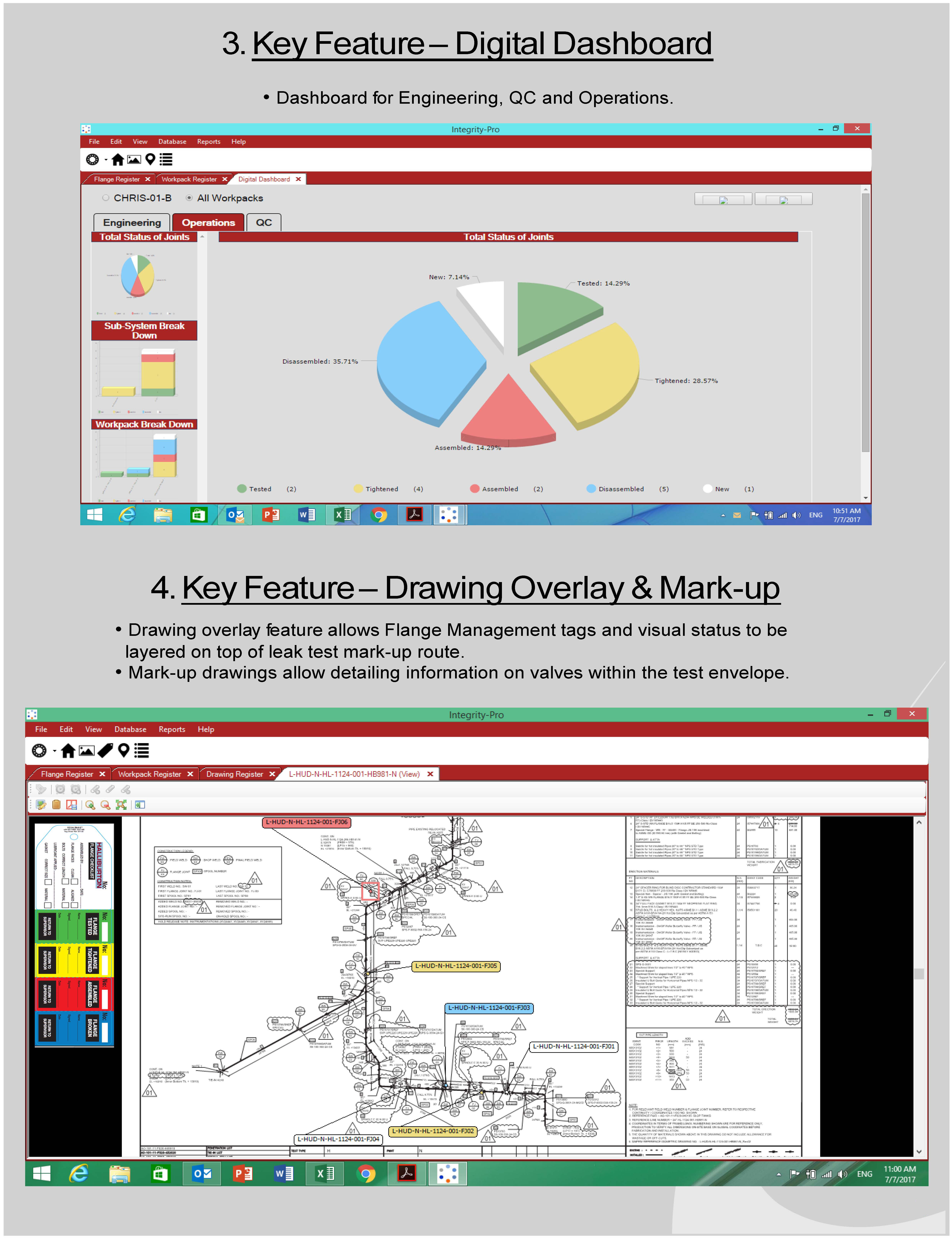

• Project control and review by visual status

display of each joint.

• Performs as a central source for documentation and records associated with each activity or task.

• Provides joint tightening procedures and methods.

• Generates tooling lists.

• Provides and maintains historical data for each joint.

• Search engine to find and display specific flanges/records.

Embedded equipment database providing access to service records, tool calibration, etc..

• Embedded personnel database providing access to individual training, competence, qualifications, etc..

• Completed joint databases can be viewed and interrogated by a freeware viewer which can be freely distributed throughout the organization.